Smart Edge – REF

Purpose

The New Zealand Roofing Association and New Zealand Construction Industry requires that a roofing paper or roofing underlay be installed under metal or concrete roofing surfaces to protect the roof framing timbers and interior of the building from the build-up of condensation on the underside of the roofing product. The underlay or roofing paper is required to direct this moisture into the gutter system and outside the building envelope.

SMART EDGE – R.E.F™ has been created following the discovery of numerous failures with roofing underlays in New Zealand during building investigations involving “leaky buildings”.

The roofing underlays or roofing paper from investigated buildings have not been providing adequate relief for the egress of the moisture build-up from the roof condensation. Observation included not only product deterioration, but also construction method failure with the paper or membrane being installed incorrectly.

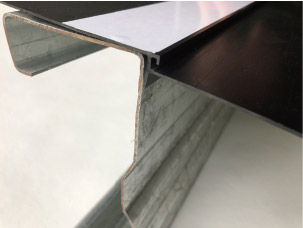

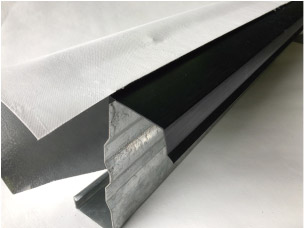

The SMART EDGE – R.E.F™ alleviates the problem of the roofing paper or underlay deterioration and installation error. It allows for the moisture or water formed on the underside of the roofing product to discharge into the guttering system by picking up the moisture discharge from the roofing paper and delivering it outside the building. The SMART EDGE – R.E.F™ also provides a separation barrier between metal to metal roof edge junctions.

SMART EDGE – R.E.F™ is a purpose designed roof edge flashing that incorporates several design features that makes it successful.

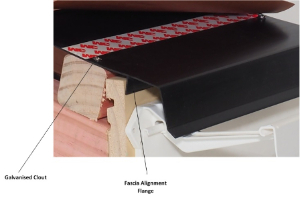

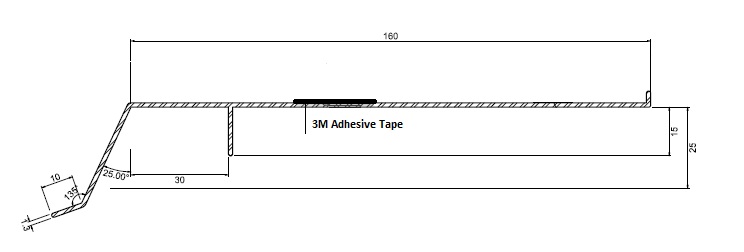

The fascia alignment flange sits hard against the fascia board to provide simple and easy alignment of the SMART EDGE – R.E.F™ which comes in 2.8m lengths.

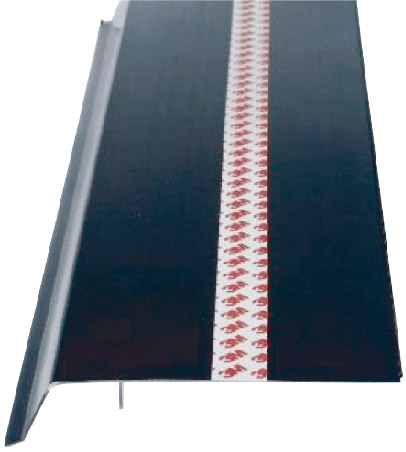

Our inclusion of a double sided tape enables roofing wraps and papers to be adhered securely to the SMART EDGE – R.E.F™ while the roof covering is installed.

The top edge of the SMART EDGE – R.E.F™ incorporates a 3mm turn up to prevent moisture tracking up the flashing into the roof space.

Design and Materials

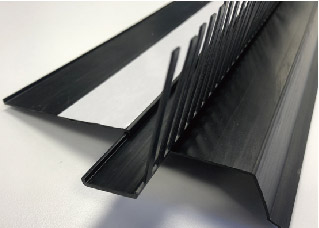

The SMART EDGE – R.E.F™ is made from a ridged UV stabilised PVC and is compatible with all known roofing materials. With PVC there is no rusting or corroding caused from contact or run off from incompatible materials so the SMART EDGE – R.E.F™ can also be used as an intermediary layer between dis-similar metals or products.

The PVC includes ultra violet light protection to provide durability as required under the NZ Building and Roofing codes of good practice.

commercial use

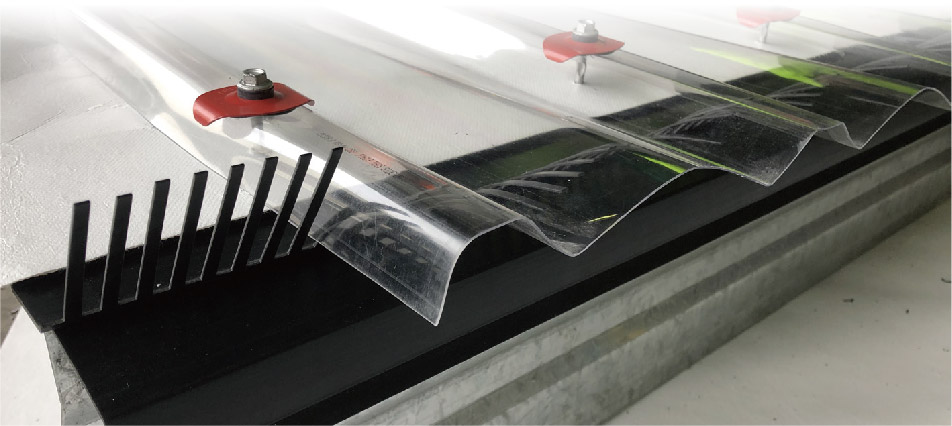

● Unique integrated design includes eaves comb to:

- prevent vermin, birds and large insects from nesting in rib voids

- aids in roof ventilation

● Eaves comb can be clipped or slid into position once flashing is installed

- eliminates the need to independently fix eaves comb

● 50mm self-adhesive tape to adhere roof underlay prior to installing the sheet

- slot provides a guide to trim underlay prior to installing the eaves comb

● Suit all roof types and adapts to any profile

● Made from fire retardant PVC which is UV stabilised

- lightweight and easy to handle

- protects vulnerable unwashed areas of the underside of the roof behind gutter

RESIDENTIAL use

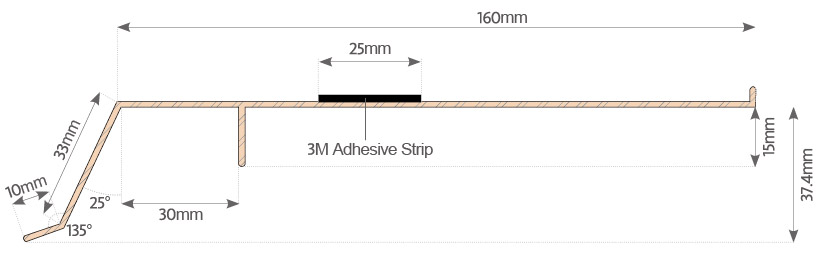

● Unique integrated design

● 25mm self-adhesive tape to adhere roof underlay prior to installing roof iront

● Suit all roof types and adapts to any profile

● Made from fire retardant PVC which is UV stabilised

- lightweight and easy to handle

- protects vulnerable unwashed areas of the underside of the roof behind gutter

Installation

The SMART EDGE – R.E.F™ is installed around the entire perimeter of a building as well as along any roof valleys.

The SMART EDGE – R.E.F™ is installed on top of the last purlin or tile batten or under the last tile batten if required.

Installation process

1. Each 2.8m length of SMART EDGE – R.E.F™ is held firmly against the front face of the previous installed fascia and fixed in place with a galvanised clout into the purlin or truss. Fixings should be as high as possible on the flashing.

2. The double sided tape should have the front face removed by 130mm to allow the next length of SMART EDGE – R.E.F™ installed and lapped by 100mm

3. The fascia alignment flange must also be removed for 100mm. This is easily done carefully with a sharp blade.

Repeat this process around the entire perimeter

Jointing Hips

5. This should be done in a similar way except the SMART EDGE – R.E.F™ needs to be mitred and does not overlap itself. The PVC jointing tape should be applied as previously noted.

Roofing Paper or Membrane Installation

6. The 3M adhesive tape protective strip should be completely removed during the installation of the roofing paper or membrane and the membrane paper firmly pressed onto it.

7. Any excess paper should be CAREFULLY cut off at the front edge of the SMART EDGE – R.E.F™ so as not to cause damage. (If damage occurs, a section of the flashing must be replaced)

8. The roofing iron or tiles can then be installed as per the manufacturer’s instructions, and then guttering as per specifications.

Anti-Ponding Boards

The SMART EDGE – R.E.F™ is not an Anti-Ponding Board.

Anti-Ponding boards which are noted for various applications, are built to prevent the roofing underlay or roofing paper from ponding as the paper travels under the second to last purlin and then over the last purlin and out into the gutter.

The SMART EDGE – R.E.F™ can provide assistance to the anti-ponding board if one is installed.

Building Regulations

(New Zealand Building Code – NZBC)

SMART EDGE – R.E.F™ (Roof Edge Flashing) meets the following requirements. (with the exception of the LRV)

NZS E2AS1 Third Edition 2011 4.3.1 Acceptable Flashing Materials, Table 20 Upvc Durability 50 years (sheltered) and 8.4.11a Flashing requirements (Figure 45a)

Clause B2.3.1c Durability Performance

Clause F2 Hazardous Building Materials: F2.3.1 Smart Edge – R.E.F™ meet this requirement and will not present a health hazard to people.

Contact

Urban Building Products Ltd

60 Kerwyn Ave

East Tamaki

Manukau 2013

Phone: 09 277 7538

Fax: 09 277 7539